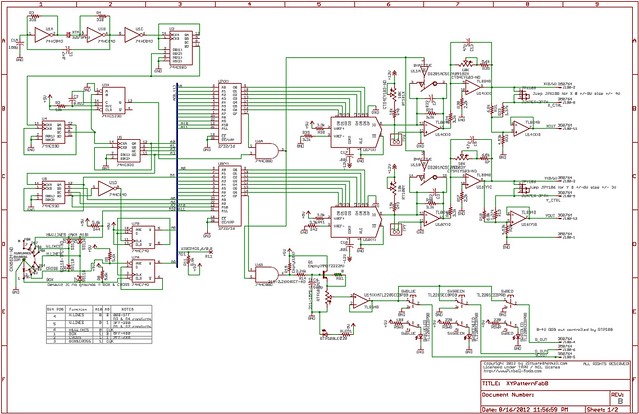

Almost a year ago I posted in my Star Trek Captains’ Chair worklog that I intended to modernize a old XY Pattern Generator design on the interwebs. Many of the guys on VectorList provided valuable insight into the interworkings of the circuit… and provided many layers of helpful advice.

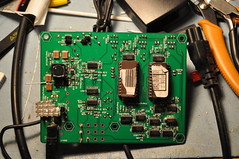

The result was a working prototype board from BatchPCB.com as a dual sided board. Surface Mount ( yes; I can hear the screams of horror ) as I wanted to minimize PCB size and thereby cost.

There were several key learnings that I’ve noted while building, debugging, and using the Vector Pattern Generator. These learning were as follows and have been incorprated into the FabB design:

- The clock generator circuit (3.578MHz xtal) and U1ABC was not “locking”. This was due to the buffered logic of the newer 74HC* logic. Some research on the internet indicated I needed a 150pf cap from pin1 U1A to ground to allow the clock generator to exite enough to lock.

- The -12V buck converting power supply wasn’t outputing the correct voltage. It’d start out at ~11V…. the drop to ~5V over several minutes. On my debugged board; shorting R26 (10meg ohm) allows the -12V to become rock steady at -11.8V. Unsure here; the Maxim EE sim was very specific on the 10meg ohm value… but the maxim datasheet indicated two modes for VL to operate in. So for now will error on the practical side.

- The 5V regulator did not have enough copper to heatsink to. FAB B has a large 5V copper heatsink built into the board for the linear regulator. For my prototype; I thermal epoxied a small heatsink from a old motherboard onto the top of the regulator to give it some thermal sink.

- The Linear POT datasheet was missing details regarding the LED side of the POT. One hole was off and was moved to match the device.

I also included the following “Nice to Haves” into the FabB design:

- Retrofitted EPROM sockets to enable A11 for a 27C32 eprom(s)… allowing for more user designed test patterns.

NOTE: A11 is hardwired to high to match 2716 eproms configurations. No clock/decode is provided for A11. Future FabC work if a solution can be found.

At this time you can use either 2716 or 2732 eproms in this design. - Renamed topside adj pots to indicate X and Y.

- Converted to 3pin jumpers so the jumpers can be mechanically sound when output swing is not shorted.

I have decided to release my portions of this design under to the public under the TAPR Non-Commercial Open Hardware License which indicates:

You may make products based upon this design, provided you do not make more than ten units in any twelve month period for your personal use.

If you agree with the license terms and are interested in the FabB schematics; they are here:

For those without PCB layout tools; a bare PCB is available from the batchpcb service for under $65. You can purchase the boards from this link:

http://batchpcb.com/index.php/Products/91905

The Bill Of Materials (BOM) of the board is available from Digikey for $75.51 (as of this post).

A bom is included with the schematics PDF above, but An XLS file with the digikey part numbers with the complete package of the materials above as a single download: XYpatternFabB_pkg.ZIP

You will need to source your own 2716 or 2732 EPROMs as Digikey does not carry them. You’ll also need to source your own 14-16VDC wallwort … you may already have a donor in your parts bin leftover from a defunct piece of equipment.

ROM images for the EPROMs can be downloaded from several sources. Hint: Do a search for XY ROM images .zip in Google.

Use the ROM images as-is for 2716 EPROMs. For 2732 EPROMs; just dup the roms using the following dos commands (as an example):

copy /B X.BIN+X.BIN x32.bin

/B is important as it tells copy that the files are binary, not ASCII files.

The Author is still using the FabA prototype; he has not yet built FabB so YMMV. The changes from FabA were relatively simple; so building these should be a low risk.

The active components (switches, linear pot, adjustment pots, jumpers, and video connector) are all populated on the reverse side. This will allow me to put the board on standoffs and a acrylic top on the device to protect it from dust/flying multimeter/scope probes.

The board is still quite big even with the surface mount components measuring 5.1×3.9in tall. By far the largest parts on the board are the EPROMs… maybe one day I’ll figure out how to move the EPROMS into a single EEPROM device and surface mount it.

So; what does the Fab A prototype look like?

Click to see higher rez pictures

This is the primary side; which faces the workbench in normal operation.

This is the secondary side. It becomes the “top” of the unit so the user can adjust settings and the like.

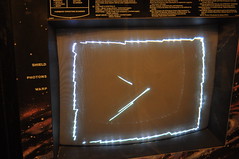

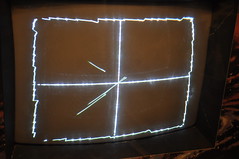

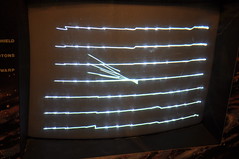

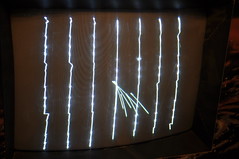

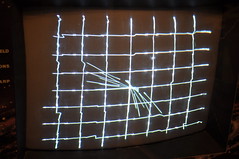

Please Note: This implementation is not perfect… there are some issues with the vector generation that I haven’t been able to debug. The imperfection does not really limit the functionality; as you can easily converge and debug a vector monitor with the vectors. I am hopeful someone can help me debug the issues so we can release a better project long term.

Overall the generator worked quite well as I was able to get my ElectroHome G08 monitor converged.

I can’t explain the center vectors… nor why the lines become squiggly. They don’t move; it’s always that way.

Strange that the site pattern doesn’t seem to suffer from odd vectors.

As you can see; the generator works well enough to converge a vector monitor…

At this point I’m not sure if the odd vectors / none straight vectors are the result of a software problem (EPROM images) or a hardware problem.

It’s possible the software isn’t reacting well with the faster hardware (HC logic, better opamps); but unsure.

Things I still need to do [if I ever find the time]:

- check the +12V portion of the buck converter. Right now I’m using the backup +12V linear regulator (U9).

- Create an enclosure to house the unit.

- Figure out how to clock A11 to enable full 2732 support; thereby more test patterns.

- Figure out why the vectors aren’t “clean”.